MTC16 Datasheet

The Mectric MTC16 is a fully programmable Transmission Control Module aimed at controlling the most complex transmission and driveline components. Designed with an over abundant amount of processing power to allow for the implementation of extremely complex, no compromise control strategies.

Overview

- 2x 650 MHz 32bit Automotive Processors

- Xilinx 7 Series FPGA

- 512 MB DDR3 RAM

- 8 GB Data Logging Memory

- Fully protected power supply inputs

- 16x Low Side Proportional Current Solenoid Outputs

- 8x Half-Bridge Auxiliary Outputs

- 4x Protected Solenoid Power Supply Outputs

- 4x Analogue Outputs

- 16x Analogue Inputs

- 16x Digital Inputs

- 4x 2 Wire Hall Effect Wheel Speed Inputs

- IMU (3 Axis Accelerometer & Gyroscope)

- Onboard Barometric Pressure Sensor

- 2x CAN 2.0A/B Busses

- 1x RS232 Interface

- 2x 5V Sensor Supplies

- 1x 8V Sensor Supply

- Ethernet PC Tuning

Applications

- Dual Clutch Transmissions

- Multi-Clutch Automatic Transmissions

- Conventional Automatic Transmissions

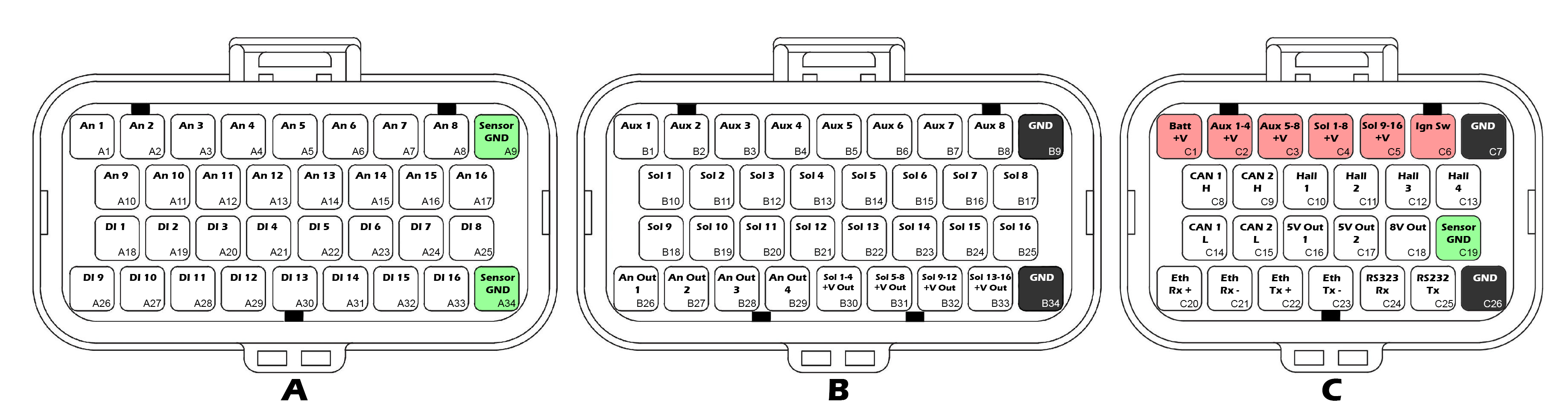

Wiring Pinout

Looking into TCM

Connector A

InfoMating Connector: 2389578-1| Pin | Function |

|---|---|

| A1 | ANV 1 |

| A2 | ANV 2 |

| A3 | ANV 3 |

| A4 | ANV 4 |

| A5 | ANV 5 |

| A6 | ANV 6 |

| A7 | ANV 7 |

| A8 | ANV 8 |

| A9 | Sensor 0V Ref |

| A10 | ANV 9 |

| A11 | ANV 10 |

| A12 | ANV 11 |

| A13 | ANV 12 |

| A14 | ANV 13 |

| A15 | ANV 14 |

| A16 | ANV 15 |

| A17 | ANV 16 |

| A18 | DI 1 |

| A19 | DI 2 |

| A20 | DI 3 |

| A21 | DI 4 |

| A22 | DI 5 |

| A23 | DI 6 |

| A24 | DI 7 |

| A25 | DI 8 |

| A26 | DI 9 |

| A27 | DI 10 |

| A28 | DI 11 |

| A29 | DI 12 |

| A30 | DI 13 |

| A31 | DI 14 |

| A32 | DI 15 |

| A33 | DI 16 |

| A34 | Sensor 0V Ref |

Connector B

InfoMating Connector: 2389578-2| Pin | Function |

|---|---|

| B1 | Aux 1 |

| B2 | Aux 2 |

| B3 | Aux 3 |

| B4 | Aux 4 |

| B5 | Aux 5 |

| B6 | Aux 6 |

| B7 | Aux 7 |

| B8 | Aux 8 |

| B9 | GND |

| B10 | Solenoid 1 |

| B11 | Solenoid 2 |

| B12 | Solenoid 3 |

| B13 | Solenoid 4 |

| B14 | Solenoid 5 |

| B15 | Solenoid 6 |

| B16 | Solenoid 7 |

| B17 | Solenoid 8 |

| B18 | Solenoid 9 |

| B19 | Solenoid 10 |

| B20 | Solenoid 11 |

| B21 | Solenoid 12 |

| B22 | Solenoid 13 |

| B23 | Solenoid 14 |

| B24 | Solenoid 15 |

| B25 | Solenoid 16 |

| B26 | Analog Out 1 |

| B27 | Analog Out 2 |

| B28 | Analog Out 3 |

| B29 | Analog Out 4 |

| B30 | Solenoid 1-4 Supply Output |

| B31 | Solenoid 5-8 Supply Output |

| B32 | Solenoid 9-12 Supply Output |

| B33 | Solenoid 13-16 Supply Output |

| B34 | GND |

Connector C

InfoMating Connector: 3-1437290-7| Pin | Function |

|---|---|

| C1 | Battery Hot Supply |

| C2 | Aux Supply |

| C3 | Aux Supply |

| C4 | Solenoid Supply |

| C5 | Solenoid Supply |

| C6 | Ignition Switch |

| C7 | GND |

| C8 | CAN 1 Hi |

| C9 | CAN 2 Hi |

| C10 | Hall 1 |

| C11 | Hall 2 |

| C12 | Hall 3 |

| C13 | Hall 4 |

| C14 | CAN 1 Lo |

| C15 | CAN 2 Lo |

| C16 | 5V0 Ref Output 1 |

| C17 | 5V0 Ref Output 2 |

| C18 | 8V0 Ref Output |

| C19 | Sensor 0V Ref |

| C20 | Ethernet Rx+ |

| C21 | Ethernet Rx- |

| C22 | Ethernet Tx+ |

| C23 | Ethernet Tx- |

| C24 | RS232 Rx |

| C25 | RS232 Tx |

| C26 | GND |

Features

Power Supply

- Reverse polarity protection

- Overvoltage protection - Clamped to 35V

- Over temperature protection

- Over current protection

- Current & voltage diagnostic monitoring

- 1x Battery constant supply

- 2x Auxiliary output driver supplies

- 2x Solenoid supplies

- 1x Ignition switch input

- 24V Compatible

Processor

- Duel 650 MHz, 32bit Automotive Processors

- Xilinx 7 Series FPGA

- 512MB DDR3 RAM

Solenoid Outputs

16x Proportional Current Solenoid Drivers

- 0.1 – 20 KHz PWM

- Low side only

- 1.8A continuous

- Current monitoring and control on all pins

- Flywheel diodes connected to solenoid power supply outputs (see below)

- Unused solenoid outputs can be used as low side auxiliary outputs

Solenoid Power Supply Outputs x4

4x Protected Solenoid Supply Outputs

- Protected and monitored solenoid supply pins

- Over current protected

- Current & voltage diagnostic monitoring

Auxiliary Outputs

8x Auxiliary Outputs

- Half-Bridge Drivers

- 0.1 – 20 KHz PWM

- High Side / Low Side 35A peak, 8A continuous

- Bi-directional current monitoring on all pins

Analog Outputs

4x Analog Outputs

- 0-5V, 10 bit, 4.88 mV resolution

- 11 mA per channel

Analog Inputs

16x Analog Inputs

- 0-5V

- 12 bit, 1.22mV resolution

- Switchable 1K pullups to 5V Out 1 on pins 1-8

- Switchable 1K pullups to 5V Out 2 on pins 9-16

- 100K Ohms to ground

Digital Inputs

16x Digital Inputs

- 0.5 – 20KHz

- 0-39V Analog Input on all pins

- 12 bit, 9.52mV resolution

- Hall effect & Reluctor sensor compatible

- Switchable 4K7 pullup to 8.0V on all pins

- Switchable 330R pulldown to GND on pins 1-8

Digital Input 1-8:

- Programmable 0-5V high trigger threshold

- Programmable 0-5V low trigger threshold

Digital Input 9-16:

- Fixed high trigger threshold: 2.4V

- Fixed low trigger threshold: 0.5V

Hall Sensor Inputs

4x 2-Wire Hall Effect Sensor Inputs

- 0.5 – 20KHz

- Open circuit detection

- Short to Battery detection

- Short to Ground detection

Inertial Measurement Unit

- 3 Axis Accelerometer, ±2/4/8/16 g

- 3 Axis Gyroscope, ±125 - ±4000 dps

On board Sensors

- Barometric Pressure Sensor

- PCB Temperature Sensor

Communications

- 10/100 Ethernet PC tuning interface, high speed, high noise immunity

- 2x CAN 2.0A/B Interfaces, fully user configurable, selectable termination.

- 1x RS232 Serial Interface

Data Logging

- 8GB Onboard eMMC logging memory.

Programming

All device configuration and firmware updates are done via ethernet connection with our free MectriCal PC Software.